Specialty steels are becoming increasingly vital across a range of critical industries, driving demand to new heights. These high-performance alloys are specifically engineered to meet the rigorous demands of sectors such as aerospace, automotive, energy, and medical technology.

As industries advance, the need for materials that offer superior strength, corrosion resistance, and durability has made specialty steels essential components in everything from jet engines to surgical instruments.

One of the primary reasons for the growing demand is the rapid technological advancements in critical industries. In aerospace, for example, the push toward higher efficiency and safety requires materials that can withstand extreme temperatures and stress.

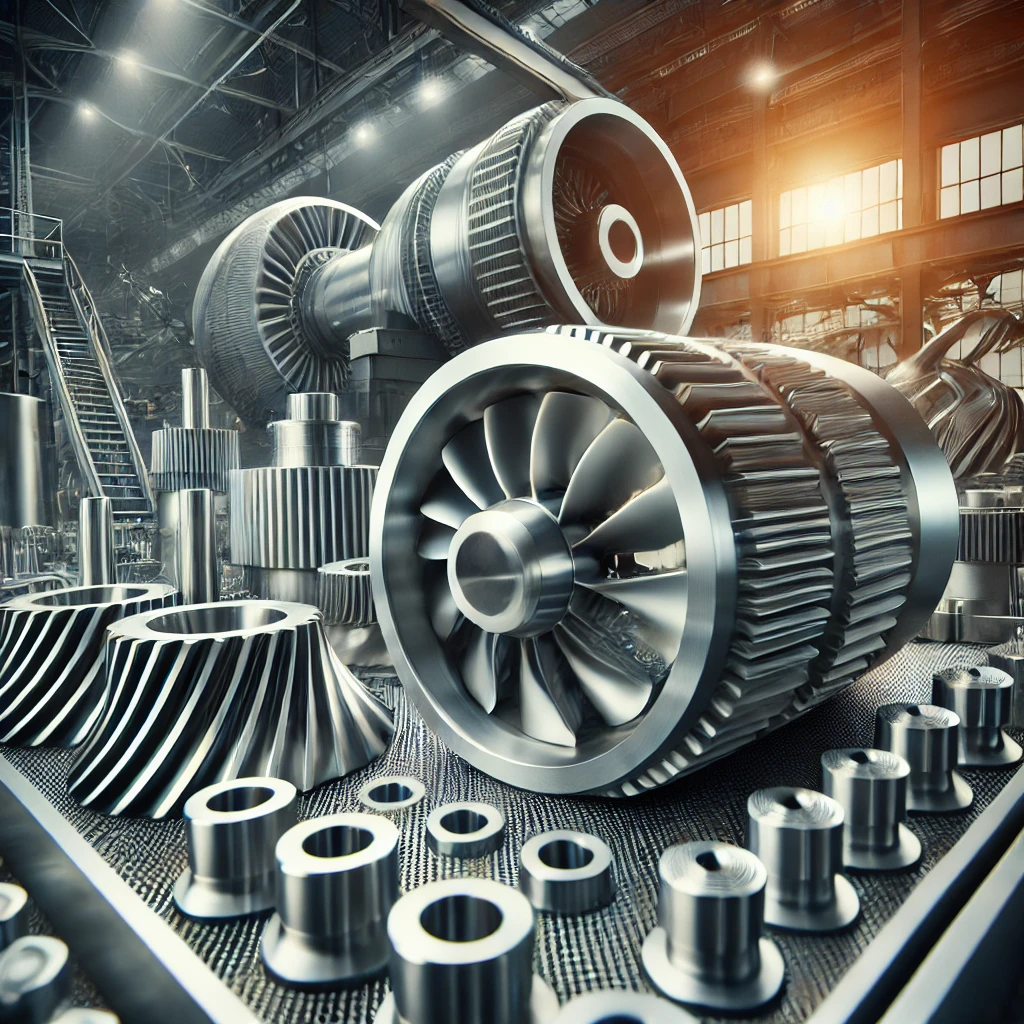

Specialty steels, like superalloys and stainless steels, are ideal for manufacturing turbine blades, structural components, and landing gear due to their excellent strength-to-weight ratios and resistance to heat.

In the energy sector, specialty steels play a key role in oil and gas exploration, renewable energy projects, and nuclear power generation. The harsh environments in which these industries operate require materials that are both tough and resistant to corrosion. From deep-sea drilling rigs to wind turbine shafts, specialty steels are indispensable in ensuring reliability and safety under challenging conditions.

Automotive manufacturers are also driving demand for specialty steels, particularly in the production of electric vehicles (EVs). As EVs require lighter yet stronger materials to enhance performance and extend battery life, advanced steels with enhanced tensile strength are becoming critical.

Additionally, the push for greener, more fuel-efficient vehicles has led to the development of hybrid and lightweight designs that heavily rely on specialty steels.

In the medical field, specialty steels are used in surgical instruments, implants, and diagnostic equipment. These materials are favored for their biocompatibility, ease of sterilization, and resistance to wear, making them ideal for use in critical applications where precision and reliability are paramount.

The global push toward sustainability is another factor driving the growth of specialty steels. With a focus on reducing emissions and improving energy efficiency, industries are seeking materials that can help achieve these goals while maintaining high performance.

Specialty steels are increasingly recognized for their recyclability and lower environmental impact, aligning with sustainability initiatives across various sectors.

The surge in demand for specialty steels highlights the crucial role they play in enabling technological progress and meeting the stringent requirements of modern industries.

As these sectors continue to innovate, the need for high-quality specialty steels is set to grow even further, making them a cornerstone of the future of manufacturing and engineering.